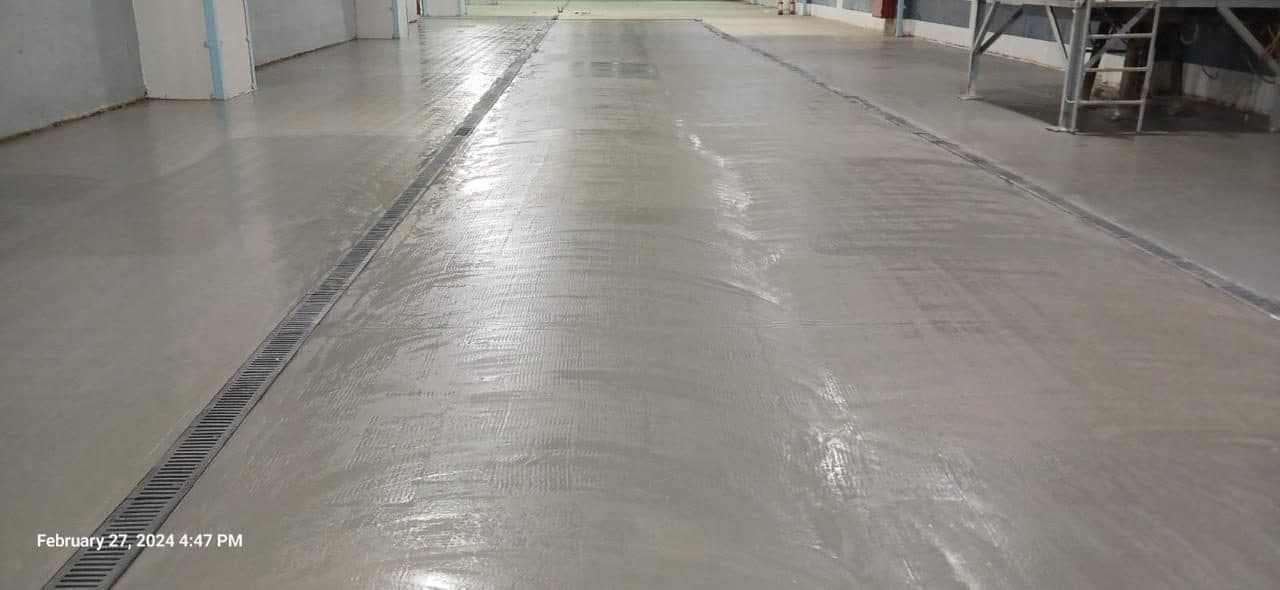

• Installation of Ucrete MF (4 mm) flooring system in production areas.

• Surface preparation using scarifier machines for grinding.

• Anchoring works around columns, circular areas, and expansion joints.

• Application of Scratch Coat (Ucrete Primer SC).

• Installation of Ucrete MF system (4 mm thickness) across the designated zones.

• Application of sealant in expansion joints for durability.

The project was executed under a competitive tendering process with highly aggressive pricing from multiple bidders, which created strong cost pressure.

Through efficient resource management and technical expertise in Ucrete systems, the team successfully executed the works at high quality while maintaining competitive pricing, ensuring long-term durability for the client.