• Waterproofing and thermal insulation works across 750 villas.

• Surface repair using SikaGrout 544, Sika Latex, and Sika Seal 550.

• Application of cementitious waterproofing systems.

• Execution of foam concrete topping as a sustainable alternative to conventional systems.

• Full responsibility of mixing, pouring, curing, and quality control testing on-site.

1. The project required a lightweight concrete system as a cost-effective alternative to the conventional method, without exceeding project budget. Additionally, strict performance criteria were set:

2. Density ≤ 800 kg/m³

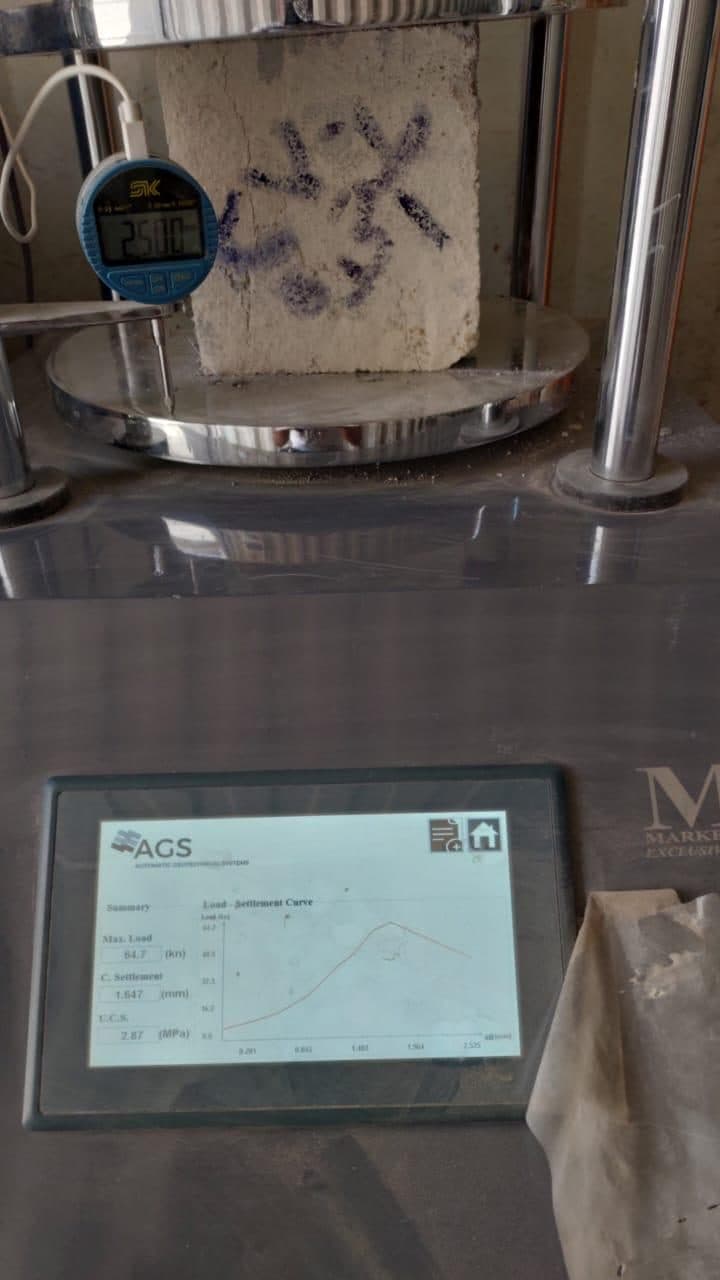

3. Compressive Strength ≥ 20 kg/cm²

The German Chemicals team established an on-site concrete laboratory inside a caravan at the project, where foam concrete was mixed, cured, and cube-tested daily. The foam concrete met all criteria — low density, high strength, no cracks — and was walkable the very next day, ensuring both durability and cost-effectiveness.